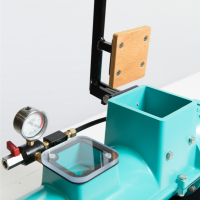

Venco De-Airing Pug Mill

Size Options

- 75mm (3″) nozzle, 136mm barrel, with a 0.18kw (1/4hp) vacuum pump

- 100mm (4 inch) nozzle 200mm barrel, with a 0.38kW (1/2 HP) sliding vane vacuum pump (Coming Soon)

Features

- Robust construction, suitable for blending, mixing and re-working clay.

- Stainless Steel auger shaft and blades.

- Stainless steel MESH shredder screen. NOT cheap perforated plates. This allows Venco pugmills to use lower capacity motors minimising operating costs.

- Zinc plated and powder coated base.

- Sealed for life ball bearings protected by “O” ring seals.

- Cast marine grade aluminium barrel – Split longitudinally for easy cleaning.

- High capacity sliding vane vacuum pumps with single phase motors – with incorporated air / water filter.

- The 100mm (4″) has access slots on the sides of the barrel for removing the shredding screens without the need to split the barrel.

Specifications - 75mm

- Model: 75mm (3 inch) nozzle , 136mm barrel de-air pug mill

- Motor: Single phase 0.37kW 240v with integral thermal overload protection

- Drive System: Industrial Gearbox

- Weight: 30kg

Warranty period: 36 months on machine

Warranty period: 12 months on vacuum pump

Specifications - 100mm: (Comming Soon)

- Model: 100mm (4 inch) nozzle, 200mm barrel De-air Pug Mill

- Motor: Single phase 1.5 kW 240v with integral thermal overload protection

- Drive System: Industrial Gearbox

Optional Extras

- Coarse shredder screens

- De-airing kit

The de-airing models incorporate a vacuum pump which removes air trapped within the clay while pugging is performed. This produces the highest quality clay for immediate use on a potters wheel.